1,5 - Step Technology

1,5 - Step Technology

What is the 1.5-Step Technologhy?

- In designing the PF Series concept our engineers carefully combined the advantages of the 1-step and 2-step manufacturing processes into the most efficient method yet devised for manufacture of PET containers. In this process, the preform is injection molded, partially cooled, temperature equalized, re-heated and blown in what is termed a “cool parison” system.

- The practical result is a very compact injection clamp system at the preform injection station, while the blow station uses 2, 3 or 4 times less blow cavities to achieve a matching output.

- This vastly reduces the mold investment cost when molding a variety of bottle shapes from common preforms. Further simplification of the molds also results in vastly reduced mold changeover times.

How 1.5-Step Machines Operate

1-Preform Injection & Primary Cooling

By separating the injection and blow processes, we designed the injection station with reduced preform pitch, allowing the use of more cavities in a high strength but compact injection clamp.

2-Secondary Cooling

Unlike other systems, the preforms undergo additional cooling by either a cooling block or by staying on a second set of injection cores even after the next injection cycle starts, allowing greater efficiency from the injection cycle and higher productivity.

3-Preform Temperature Stabilization & Pitch Adjustment

Preforms are allowed to stabilize their temperature from skin to core, an essential requirement for stable molding and optimized material utilization.

Where applicable pitch between preforms is changed to the blow cavity pitch.

Where applicable pitch between preforms is changed to the blow cavity pitch.

4. Preform Re-heating

Infra-red heating by halogen heating lamps allows precise and consistent control of wall thickness, heating lamps are fully adjustable for position and power setting.

5. Preform Temperature Stabilization & Special Processing

A variety of specialized processing techniques can be added here, including; Neck Orientation, Spot Cooling*, Handle Orientation*, Preferential Heating, Handle Inserter Device and others. Additionally, the preform skin temperature is allowed to stabilize with the core temperature once more.

6. Stretch Blow Molding

Either at step 3 or step 5, the pitch of the preforms is changed from the injection mold pitch to the blow mold pitch. Blow molds may be cooled (standard) or heated where special molding requirements exist such as semi-heat set.

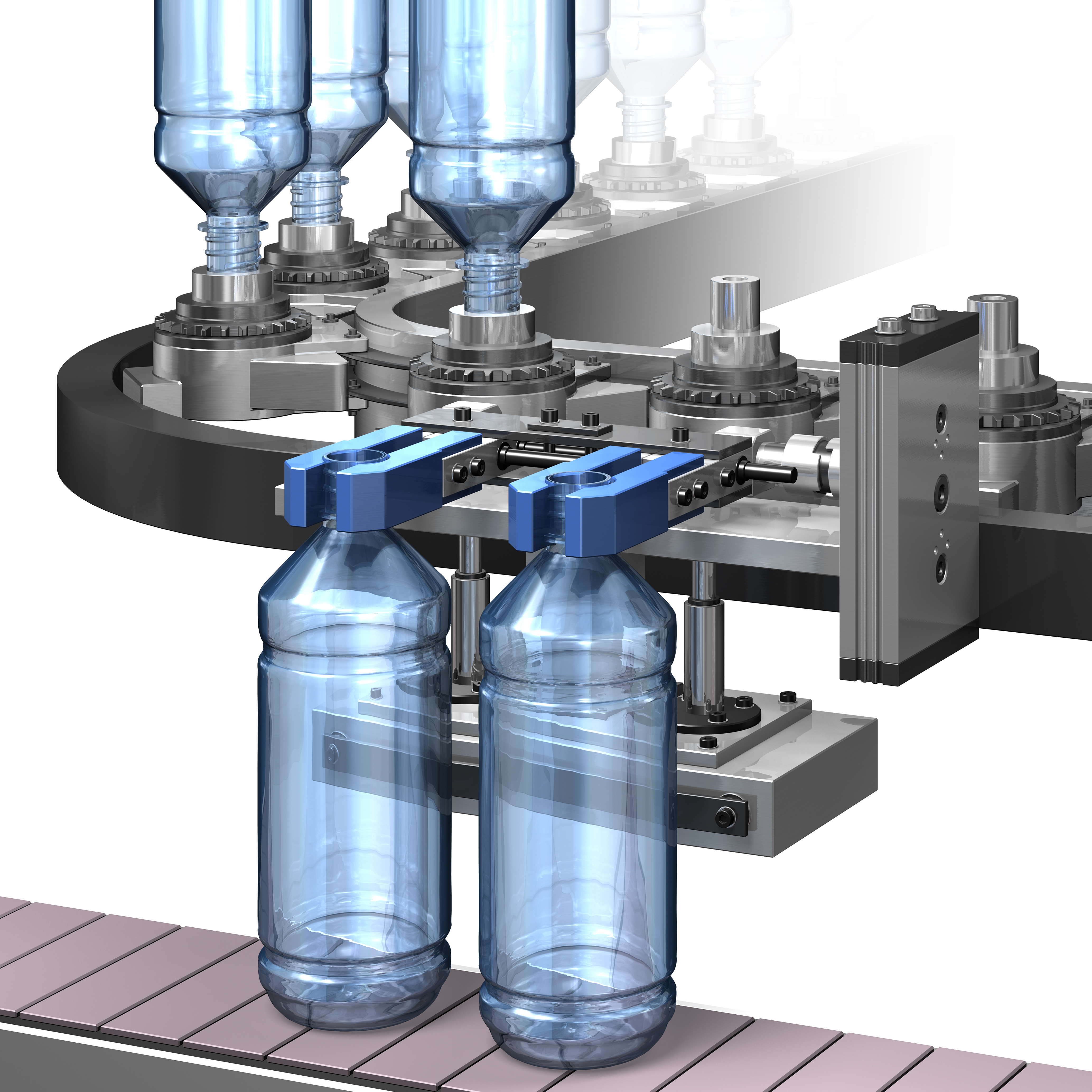

7. Container Eject

Containers are removed from the machine and can be placed onto an optional take-out conveyor.

EN

EN