2-Step Double Blow Heat-Set Technology

2-Step Double Blow Heat-Set Technology

What is the 2-Step Double Blow Heat-Set Technology?

- ASB's Double-Blow Technology includes the first and second mold systems.

In this process, temperature adjustment is carried out at a high level in the first mold. In the second mold, the container is blown again to reduce shrinkage and internal stress, allowing it to take its final shape.

Thanks to the double-blow technology, it is possible to produce heat-resistant bottles and jars. - ASB has been continually developing and refining the double blow heat-setting method over more than two decades. Containers produced by this method have unique properties that expand the uses of PET resin into new market segments.

- Heat-Set bottles and jars are commonly used for filling juices, teas, pickles, sauces and other bacteria sensitive products under pasteurized conditions.

How 2-Step Double Blow Heat Set Machines Operate

1-Preform Injection

A PM Series preform molding machine may be used to injection mold the preform (as per normal 2-step molding). If neck crystallization is required, the molded neck diameter will typically be slightly larger than the target neck size.

2-Neck Crystallization (option)

A CM Series neck crystallizer is used. Neck crystallization is not always required - the determining factors are neck diameter and design, filling procedure and what type of cap is to be used.

3-Blow Molding

Using one of our HSB Series blow molding machines, the preform is re-heated and stretch blow molded. Refer to the following three steps for details of the HSB process.

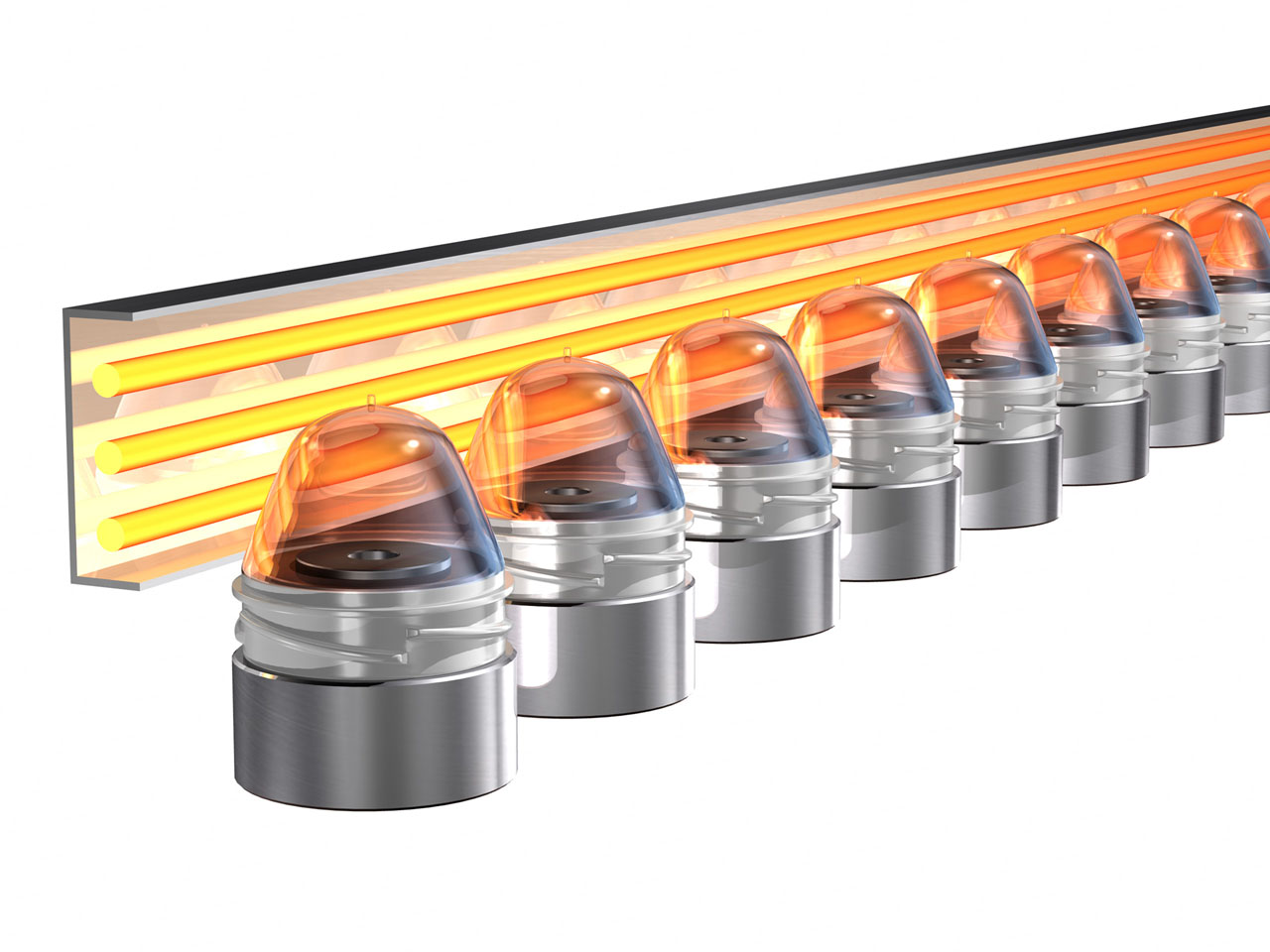

a. Preform Re-heating

The preform is re-heated to a temperature suitable for stretch blow molding. Up to this point, the molding process has been identical to conventional 2-step stretch blow molding but from here onward it becomes different.

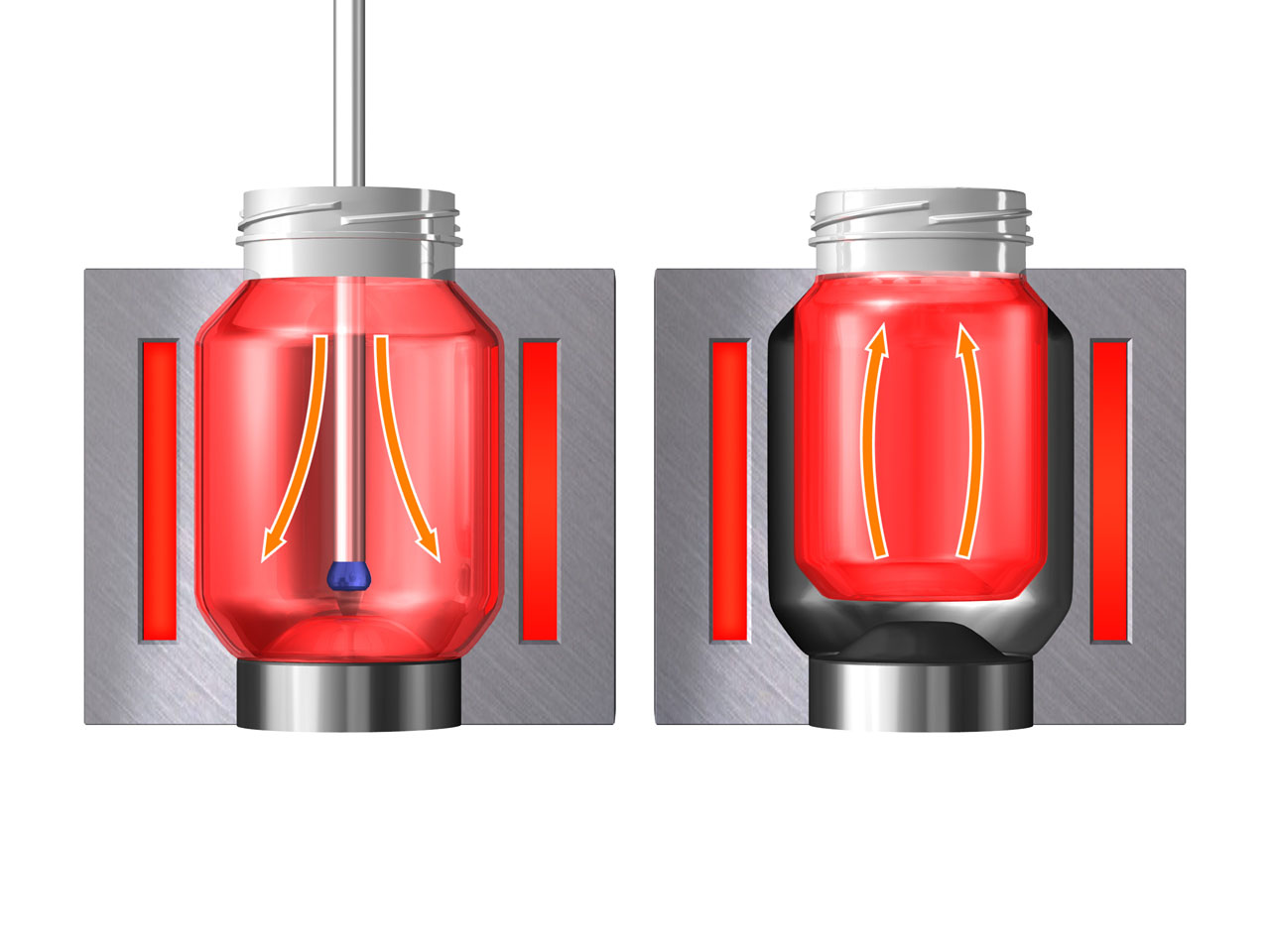

b.1st Blow (Heated)

In an HSB Series machine, the primary blow mold is electrically heated in excess of 175°C, it is also larger than the target container size by around 20%. After blowing is completed, the pressurized air is exhausted from the container but the blow mold remains closed a little longer. The high temperature causes partial crystallization of the resin, additionally, the container shrinks which has the effect of removing stress from the PET polymer chains.

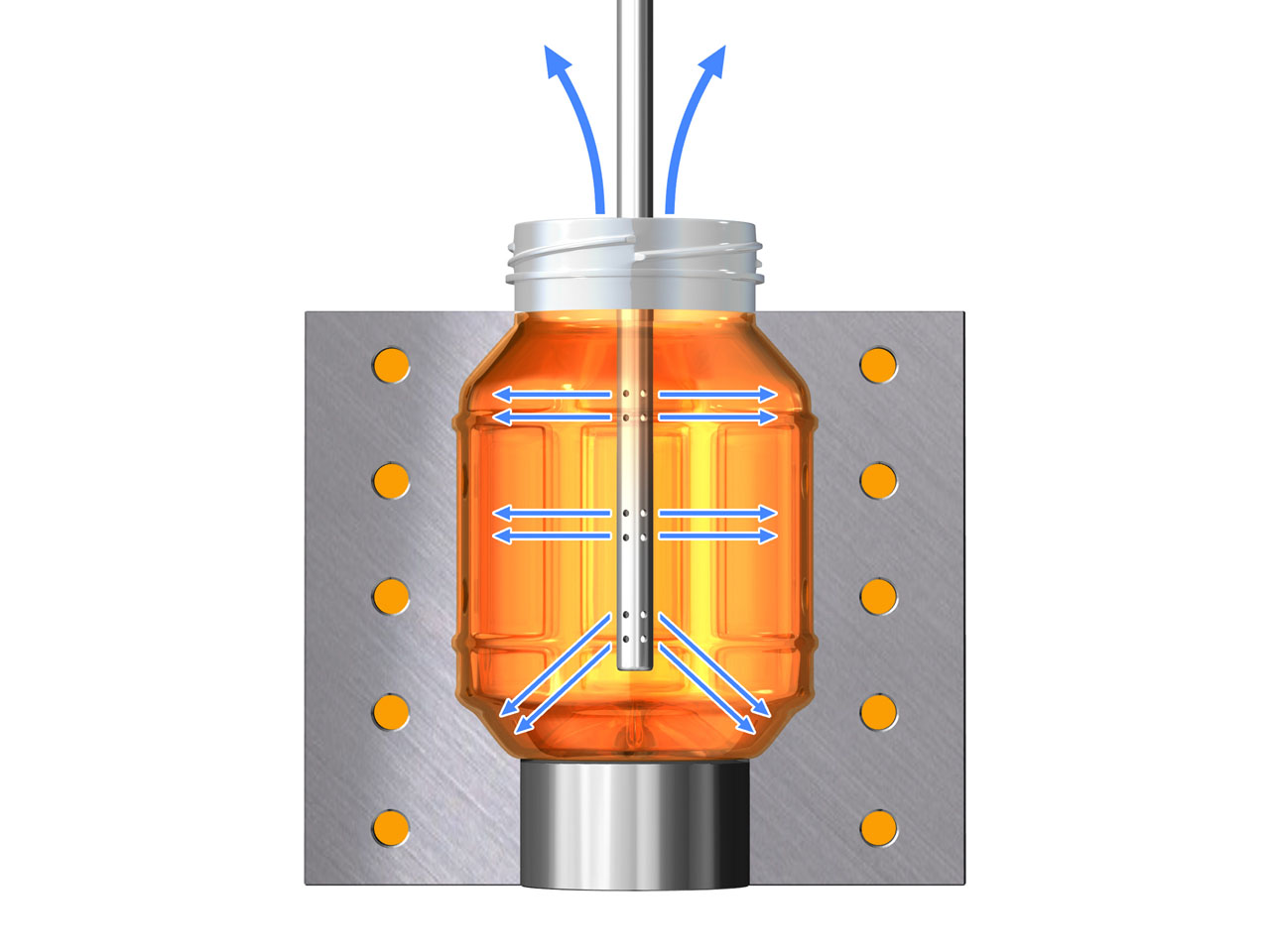

c.2nd Blow (Conditioned)

In an HSB Series machine, the primary blow mold is electrically heated in excess of 175°C, it is also larger than the target container size by around 20%. After blowing is completed, the pressurized air is exhausted from the container but the blow mold remains closed a little longer. The high temperature causes partial crystallization of the resin, additionally, the container shrinks which has the effect of removing stress from the PET polymer chains.

EN

EN